A Beginner’s Guide to 3D Printing

3D printing is an exciting new technology that can revolutionize your life. However, it’s also a lot more complicated than you might think.

This article is designed to help you cut through the hype and make an informed decision when it comes time to buy your first 3D printer.

What Is 3D Printing?

3D printing is a manufacturing process that uses digital files to produce three-dimensional objects. Often referred to as additive manufacturing, it’s an effective way to create complex parts, saving time and money while reducing waste.

The most common use of 3D printing is in rapid prototyping, where digital files are used to quickly create models or prototypes that can be tested and validated. This can help product designers and engineers get their products to market faster.

Many industrial OEMs are already using 3D printing in their production processes to stay agile and responsive, helping to keep production costs down while increasing productivity. The rapid production of prototypes and models can also help manufacturers identify and fix design issues that would otherwise have taken weeks to implement with traditional manufacturing methods.

As 3D printing enables manufacturers to create parts on demand, this means they can reduce inventory levels and warehouse space, while improving inventory management and reducing shipping and air travel. In addition, it can help reduce the environmental impact of manufacturing.

Another key use case for 3D printing is in the medical industry, where it can allow patients to receive custom devices that are shaped to suit their unique needs. One example is clear aligners, which are designed to straighten teeth and adjust them when needed.

In the future, 3D printers may also be able to produce artificial body parts, which can mimic natural tissues, allowing for better osseointegration. This technology could one day be used to replace damaged bone or ligaments.

How Does 3D Printing Work?

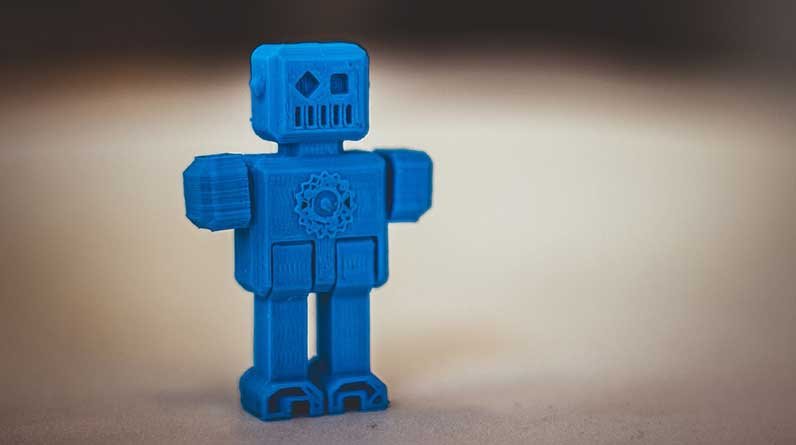

There are many different types of 3D printers, but all share the ability to turn digital files containing three-dimensional data — whether created on a computer-aided design (CAD) or computer-aided manufacturing (CAM) program, or from a 3D scanner — into physical objects. These printers can be used for a variety of applications, including product prototypes, tooling and molds, architectural models and toys.

Unlike traditional methods of manufacturing, which require cutting, drilling or milling material from a block of solid material, 3D printing builds up parts by depositing and fusing 2D layers of materials. This process, called additive manufacturing, has almost no startup costs or setup time and is able to create parts in virtually any geometry.

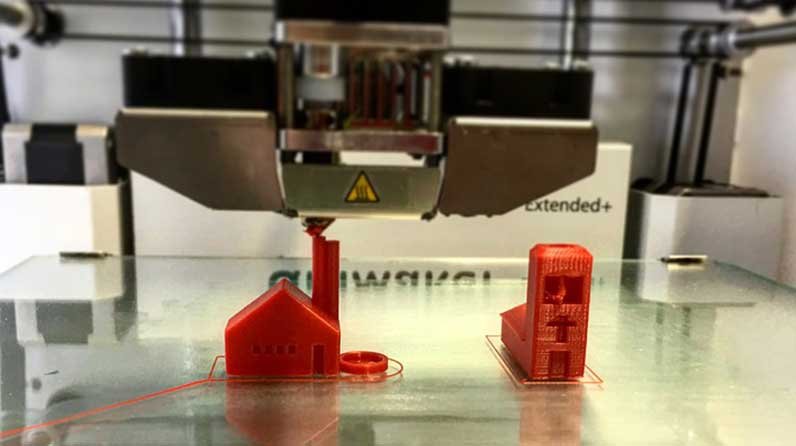

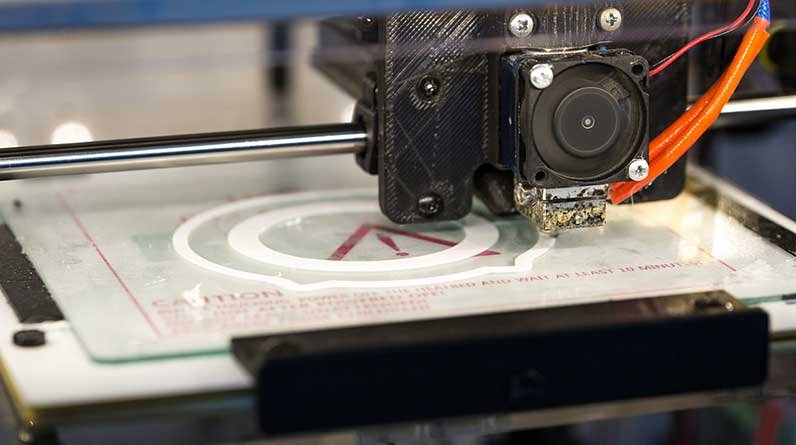

Although there are several techniques for printing, most printers use a type of additive manufacturing known as fused deposition modeling (FDM). In this technique, thermoplastic filaments are released from a heated extrusion nozzle to form an object layer by layer. The most common plastics include acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), and elastomeric polymer rubber (EPR).

Other popular techniques for 3D printing are stereolithography (SLA) and selective laser sintering (SLS). In SLA, a liquid resin is melted into plastic using a laser, while in SLS, a powder of plastic is deposited onto an already-solid structure with a laser.

These technologies have become more widely available in recent years, and are suitable for a range of applications, including rapid prototyping and the manufacture of small or bespoke production parts. Because of their high level of accuracy, they can often be more cost-effective than CNC machining or injection molding for smaller runs. They can also be produced in a fraction of the time, which can be crucial for startups and new products.

What Are the Best Materials for 3D Printing?

There are many different materials for 3D printing, and each one has its own unique properties. Some are easier to print than others, and some require special tools or post-processing.

The most common material for desktop 3D printing is PLA (Polylactic Acid), which can be found in a variety of colors and thicknesses. It’s also a more eco-friendly option than ABS and is odorless. It doesn’t require a heated bed and has low-warp properties.

Another popular material is TPU (Thermoplastic Polyurethane), which feels and acts much like flexible rubber. It’s an excellent choice for making things that can bend or must flex, such as stoppers, belts, springs, phone cases and more.

TPE is available in both 1.75mm and 3mm filament, and it’s best used when you want to create parts that are rubbery, elastic and impact resistant. It’s a great alternative to Soft PLA if you want to 3D print a part that’s more flexible and has a higher resistance to impacts than our other standard materials.

Other common 3D printing materials include PET-G (Polyethylene Terephthalate), Nylon and ASA (Acrylonitrile Butadiene Styrene). All of these are strong, durable and suitable for making production-ready prints that may need to endure a bit of heavy use.

Nitinol, or nitinol-titanium alloy, is an exceptionally flexible 3D printing material that’s a popular choice for medical implants because it can bend to great degrees without breaking. It’s also highly conductive and can be made to form very small structures.

Some other metals that can be 3D printed include aluminum and tool steel. These are both lightweight and have good thermal and corrosion resistance. They’re also easy to shape with Direct Metal Laser Sintering, or DMLS, which is an advanced metal 3D printing technology that requires less design freedom than traditional welding processes.

What Kind of 3D Printer Should I Get?

If you’re looking to get started in the world of 3D printing, it’s important to understand what type of printer is best for you. There are many different types of printers to choose from, ranging from basic home models to high-end commercial-grade machines.

The most common consumer 3D printers use fused deposition modeling (FDM), which uses plastic filament to make thin layers that form the model. Others, like resin printers, use a curing process to harden materials.

FDM printers are the most versatile and work well with a wide variety of materials. They’re also safer to operate than resin printers, since they don’t use flammable chemicals to cure the print material.

Resin printers, on the other hand, offer a smaller build volume and can be difficult to use. They’re best for detailed models like character busts, dental work and tabletop miniatures, but they’re also great for making jewelry.

You should also consider your budget when shopping for a 3D printer. The cost of a printer will depend on its size, resolution and whether it includes material or not. You can find entry-level models for as low as $200 or $300 and more expensive options that come with more advanced features.

The best printers are a mix of quality and value, so it’s important to shop around for your needs. If you’re new to 3D printing, you may want to invest in a printer with a heated print bed or easy-to-use controls that are suitable for beginners. If you’re more experienced, you should look for a 3D printer that offers a large build volume, higher resolution and faster speeds.

How Do I Get Started with 3D Printing?

When you want to get started with 3D printing, you need a printer and the right software. You also need a few materials and other tools.

First, you need to decide what material you want to print with. This can be a difficult decision because there are so many different options. The most common is PLA, but other materials such as ABS and HIPS are also available.

Next, you need to design your model using the right software. You can do this with a variety of free or cheap CAD (computer-aided design) software that will allow you to draw your model in a way that the printer will be able to recognize.

You should also know what file format your 3D printer accepts. This can be done by downloading a free trial version of a program from the manufacturer, or you can buy a commercial license.

Finally, you need to create the G-code file that will guide the printer as it tries to produce your model. You can do this with a free CAD software that is able to generate the G-code.

The G-code file will tell the printer where to place the material and what steps to take. The resulting object will be a replica of the original design. You can then print as many copies of your design as you like.

With the right resources and a little bit of patience, you can have a lot of fun with 3D printing!

In conclusion, 3D printing is an exciting and creative way to bring your designs to life. With the right printer, software, and materials, you can create anything you can imagine. With a little bit of practice, you can become an expert 3D printer and make a variety of amazing objects.