The Economics of 3D Printing

One of the main benefits of 3D printing is that it can reduce the cost of production. By using fewer materials, eliminating certain assembly steps, and shortening the supply chain, this technology offers significant cost savings.

One example of this cost saving is that it can lower the costs of producing low-demand parts. This can save a company money on shipping expenses and also free up time for other operations.

1. Cost-Effectiveness

There are many ways that 3D printing can be cost-effective, but there are a few key factors that should be considered. These include material costs, assembly costs, and tooling costs.

In addition to these, 3D printing is also often more energy efficient than traditional manufacturing methods. This can be a significant savings to manufacturers who may need to produce high-volume quantities of a product.

As 3D printing becomes more widespread, more companies are utilizing this technology to help reduce production costs and increase efficiency. This can be particularly beneficial for small businesses and start-ups.

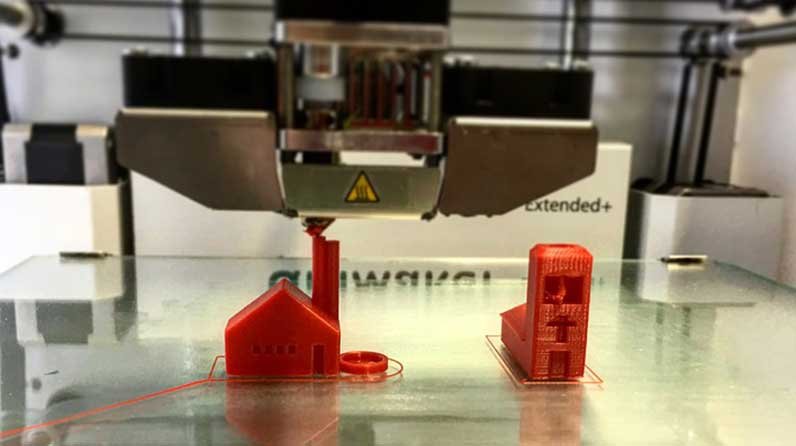

Another major benefit of 3D printing is its ability to quickly create prototypes of a product that can be tested by customers before the product is produced in a larger quantity. This can help prevent problems during the design process, which can be costly in time and money.

For example, a recent study found that surgical teams using 3D-printed models could save up to $62 per operating minute. This helps surgeons complete surgeries faster and allows more patients to receive care.

Additionally, 3D printing can be a very cost-effective way to produce custom products that are tailored to the needs of consumers. This is important for companies that are trying to provide a personalized service or offer products that are not standardized.

It can also be used to produce spare parts for legacy equipment that is out of stock or hard to find. Siemens Mobility, for example, has a dedicated RRX Rail Service Centre that uses 3D printing to manufacture spare parts and tools on demand as needed.

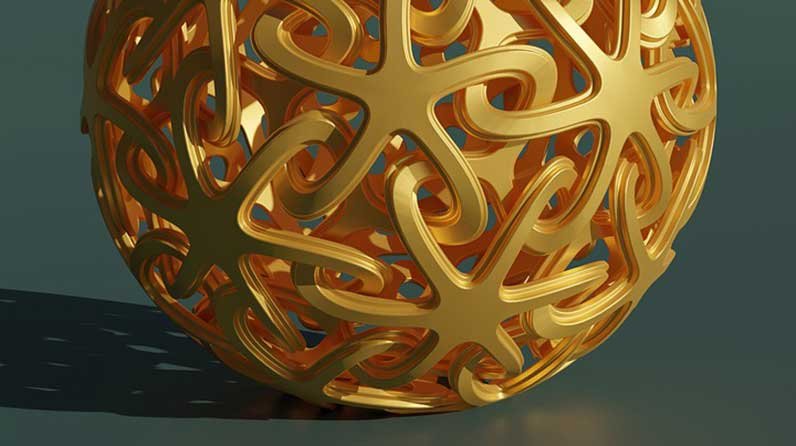

This can also be done with more complex and detailed designs that require a higher level of precision. This is a great option for engineers and designers that need to produce highly accurate, functional parts.

Finally, it is also possible to scale down a model to make it smaller, which can reduce the amount of materials used in production. This can be very helpful for industries that use large-scale machines, such as aircraft manufacturers. This can save the company money while ensuring that it still produces a quality product.

2. Flexibility

Flexible materials are becoming increasingly popular in the 3D printing industry for a variety of reasons. In particular, they are often used for prototypes that need to withstand harsh conditions. They are also used to make a variety of products that can be manipulated to accommodate specific needs.

A variety of materials can be used to make flexible parts, with TPU being one of the most common choices. In addition to being able to be molded and shaped, TPU is also resistant to abrasion.

Another advantage of flexible plastics is that they are incredibly lightweight and strong. This makes them a great choice for a variety of applications, from engineering to medical and automotive.

For example, a 3D-printed shoe sole is often made from flexible material to allow it to absorb shock without bending or breaking. This means that it will be less likely to tear, and therefore cost less in the long run.

Other types of flexible plastics are available too, including a few that are very soft and easy to print. These include Liqcreate’s Premium Flex and Flexible-X, as well as Oo-kuma’s TrueFlex.

As with any resin, it is important to understand how to assess a flexible filament’s mechanical properties and performance. This includes a number of measurements such as Shore A hardness, Elongation at break, Tear strength and Compression set.

In this way, you can use these metrics to compare different flexible filaments and choose the right one for your project. The most important thing to remember is that it is not enough to simply select a material with the same Shore A hardness. You must also pay attention to other mechanical properties that are often not represented by this hardness measurement alone.

For instance, a flexible filament that has the same Shore A hardness as a semi-flexible filament will not reproduce its mechanical properties. Similarly, a flexible filament that has the same max stress and elongation at break as a semi-flexible filament will also not produce the same result. This is because the rigidity of a resin can vary dramatically.

3. Efficiency

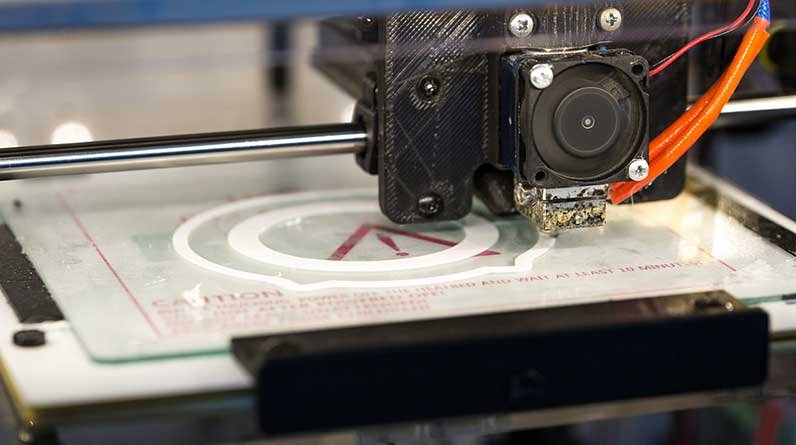

One of the main benefits of 3D printing is its ability to produce complex shapes without wasting as much material as traditional manufacturing methods. This is achieved by placing layer after layer of material, which can then be melted, fused, bound, or sintered to form the part.

This is a key benefit for industries that produce complex parts, including aerospace and defense. For example, 3D printers are able to create small, specialized parts, such as engine components, that would be too difficult or costly for injection molding. This reduces the cost of tooling and increases efficiency, allowing manufacturers to manufacture parts more frequently.

Another important benefit of 3D printing is its ability to consolidate parts into one component, reducing the number of pieces that need to be manufactured. This allows for more efficient assembly and maintenance processes and can be particularly helpful if the product has a long lifespan.

In addition to reducing the number of parts that need to be manufactured, 3D printing can also help to lower the energy consumption of the entire process. This can be especially useful in situations where the use of multiple tools is required, such as CNC machining.

Additionally, 3D printing can also be used to create hard tooling like molds, which are usually CNC milled. Traditionally, these are expensive and time-consuming to manufacture. However, 3D printing can produce these in a fraction of the time.

Many industrial goods manufacturers are already utilizing 3D printing to manufacture jigs, fixtures, and gauges for use in their production line. This is a cost-effective way of preventing expensive and lengthy delays in production, and it can also save valuable time by cutting down on design iterations.

Finally, 3D printing can also be used to print spare parts for machinery. This can be especially helpful when legacy equipment needs a repair, and it may be too difficult to procure a replacement from the manufacturer. This can reduce the inventory required, avoiding the need to store spares that are not in demand.

With all of these different benefits of 3D printing, there is no denying that the technology is becoming increasingly relevant in manufacturing. It is therefore vital that businesses take the time to learn more about the benefits it offers, and how it can be incorporated into their manufacturing processes to benefit their bottom line.

4. Sustainability

Despite the growing popularity of 3D printing, there’s still much work to be done in terms of sustainability. The first step is choosing a material that is sustainable in the long run, and that means choosing a non-toxic material that can be recycled or made from renewable resources.

Plastics are the most common material for 3D printers, but some newer options, such as plant-based materials, can help make a big difference in terms of sustainability. These newer materials can help combat plastic pollution and the problems associated with it, but they will still take a very long time to decompose.

A second way that 3D printing can be more sustainable is by producing fewer parts per product. This reduces waste in terms of materials and energy consumption since you don’t have to build the product with a large amount of material, but rather with only what is needed to produce one part at a time.

Another key aspect of 3D printing’s sustainability is that it enables companies to print locally, instead of shipping goods across the globe. Considering that transportation accounts for nearly 27 percent of greenhouse gas emissions, the ability to create a product locally can save significant fuel costs and carbon footprint.

This is also an important factor when it comes to reducing the need for packaging and shipping, as well as minimizing waste from manufacturing and storage. As an added benefit, 3D printing allows for the creation of spare or replacement parts to be printed and stored on-site, allowing for a closed-loop supply chain that uses recyclable materials.

Lastly, the use of computer-generated designs can help cut down on resource usage and energy use during the design and early production stages of a product. This can help cut down on the production and shipping costs of a product, and it can also improve its form, function, performance, and durability.

Moreover, the use of renewable materials and energy-efficient production can help manufacturers reduce the overall environmental impact of additive manufacturing. This can be especially beneficial for fast-paced consumer goods, such as dental appliances, eyewear, athletic footwear, and medical devices.